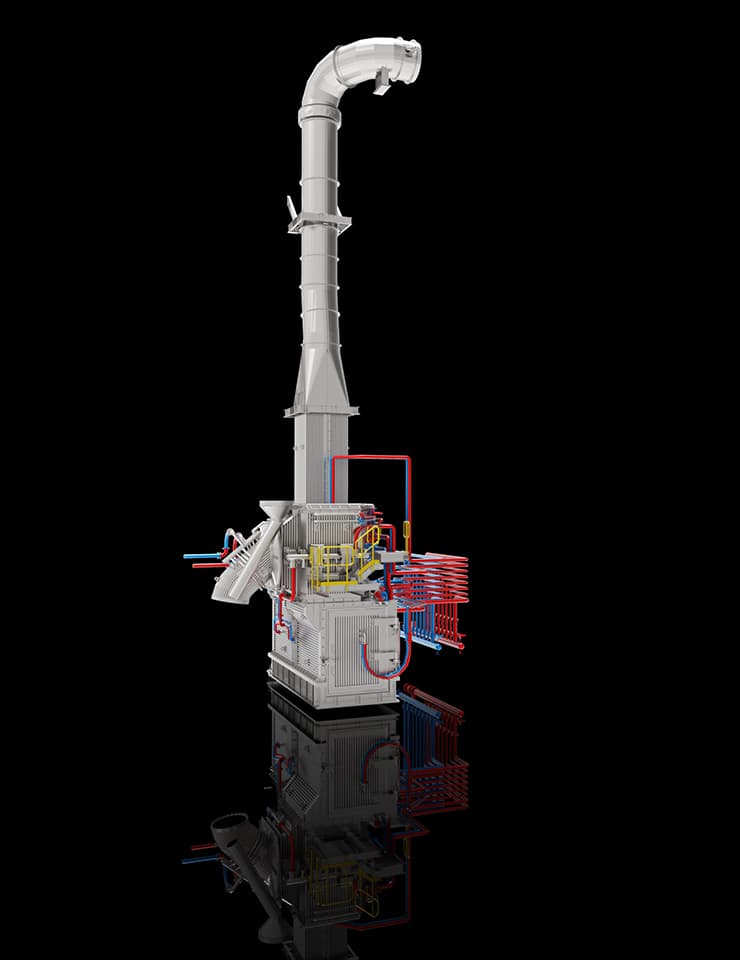

Dedusting Plants

Studio Ingia deals with the design, implementation and supply of various technological applications for the aspiration and filtration of polluting fumes and dust that derive from numerous industrial production and processing processes. Installation in compliance with current regulations is a fundamental requirement, as the dispersion of harmful substances into the air causes environmental pollution, deterioration of machinery, and concrete damage to the health of employees who are constantly exposed to them.

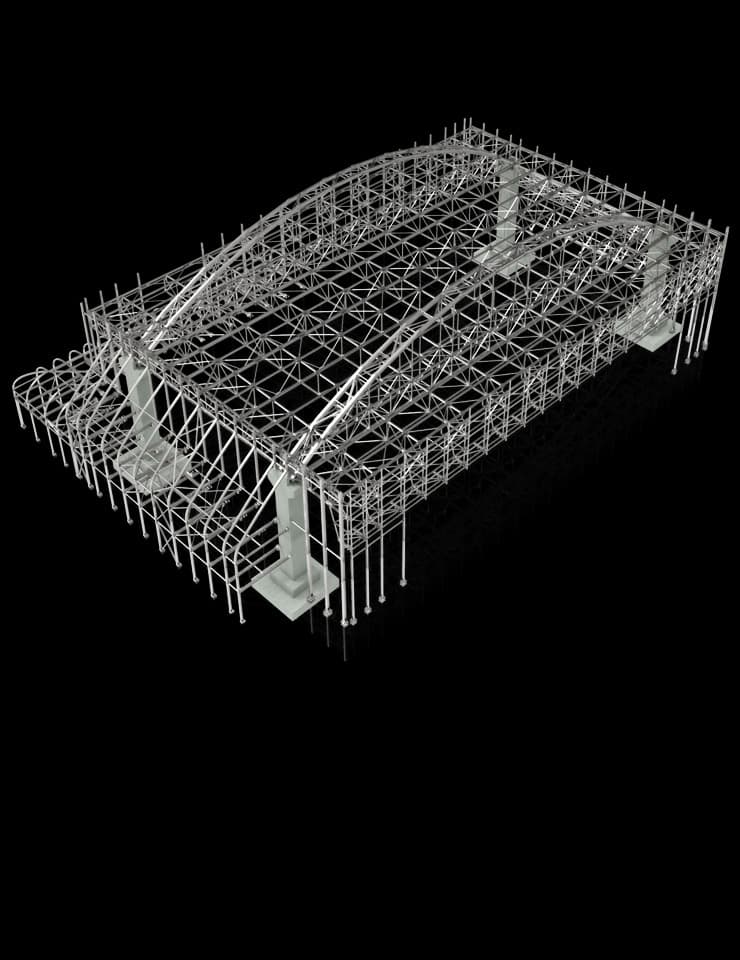

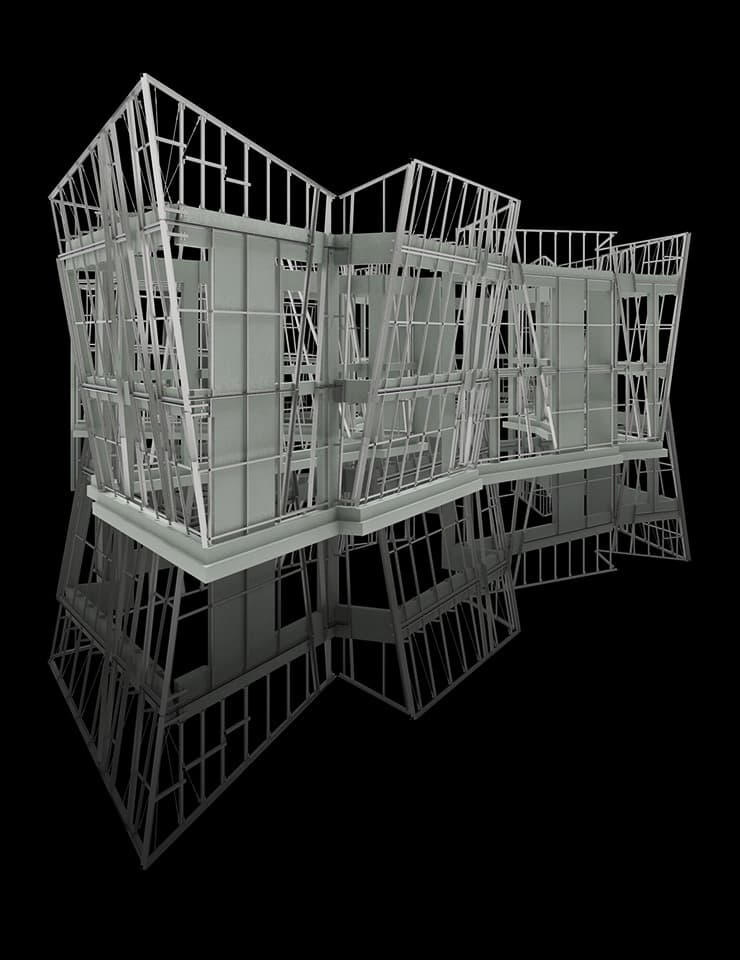

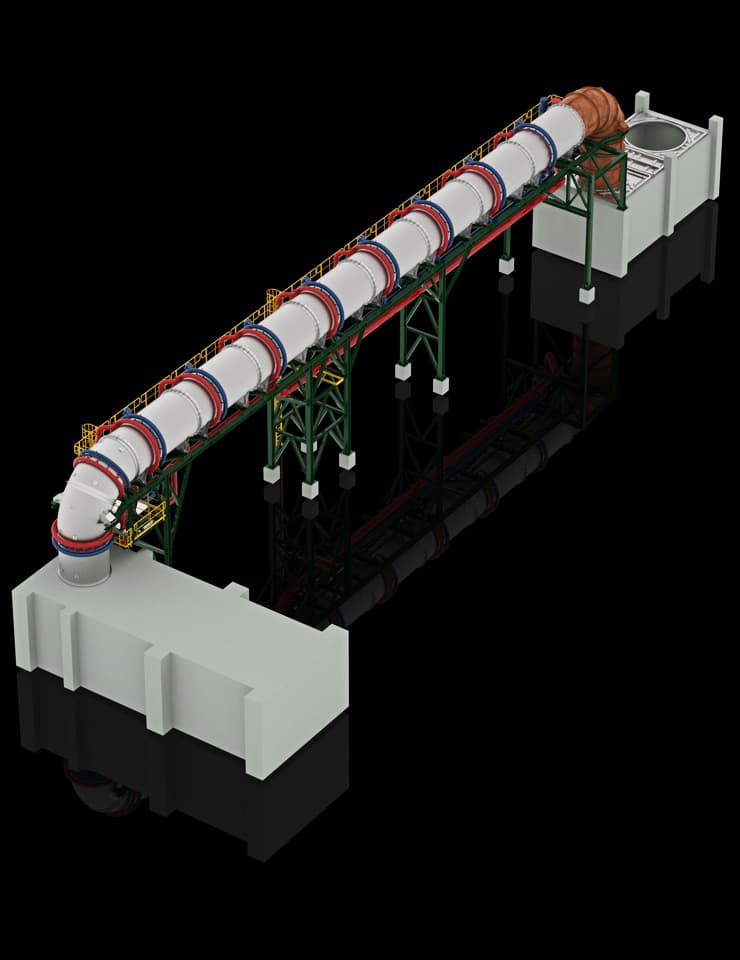

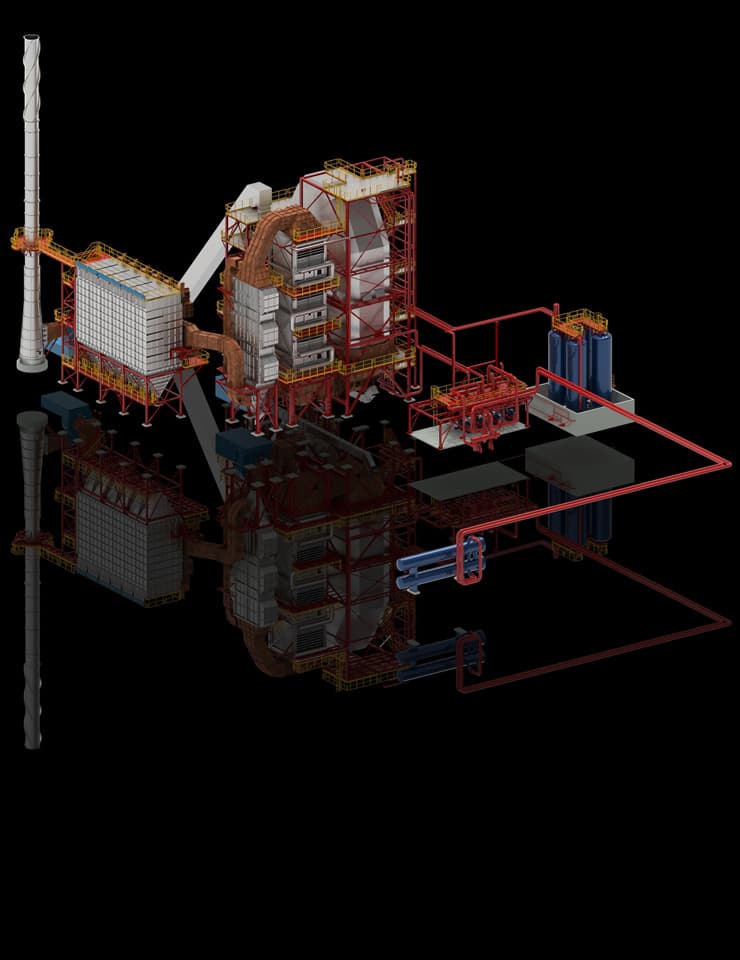

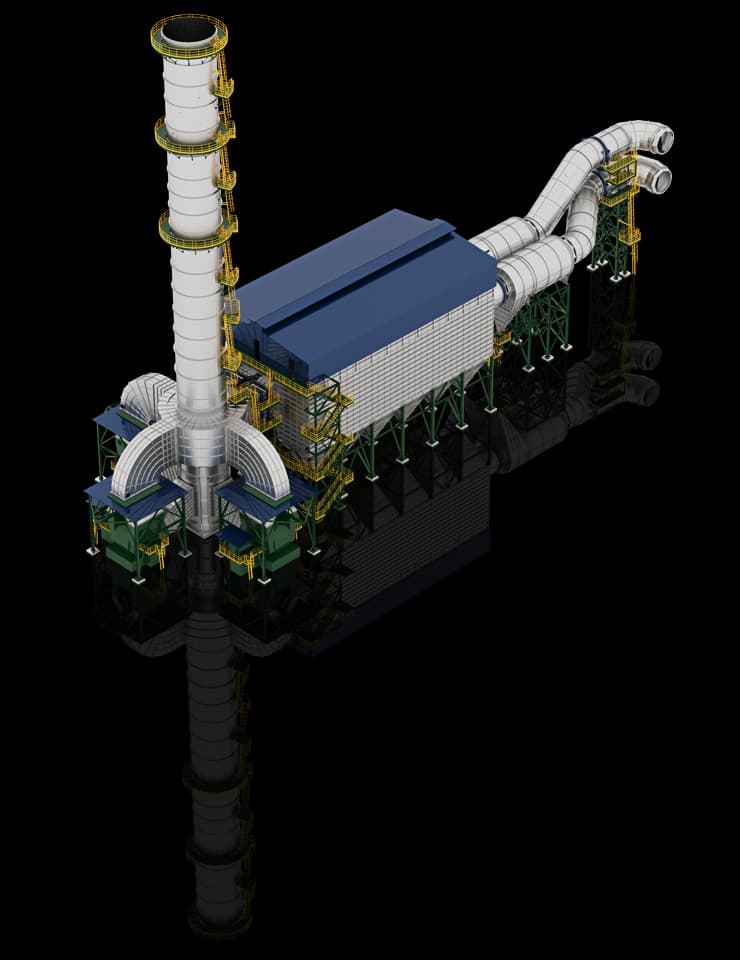

We provide various solutions depending on the type of dust produced, its quantity and concentration, and the required suction flow rate. All dust removal systems are modular and scalable to best adapt to business premises. Dust reduction systems are installed downstream of the entire dust collection system, and the choice of filter is linked to the type of dust, fumes, and substances collected (such as dust collection, laser cutting and plasma cutting, dust collection in steel mills, cement plants, steelworks, foundries, carpentry, footwear, plastics, waste, marble) and to the emissions limits established by law (references DLS 152/2006 and DLS 4/2008).

Another fundamental parameter in choosing the correct dust reduction system is the analysis of the quality of the dust, which, if it is ATEX, i.e. potentially explosive dust, will be treated with ATEX filters corresponding to the requirements of European directives ATEX 94/9/EC and ATEX 99/92/EC).

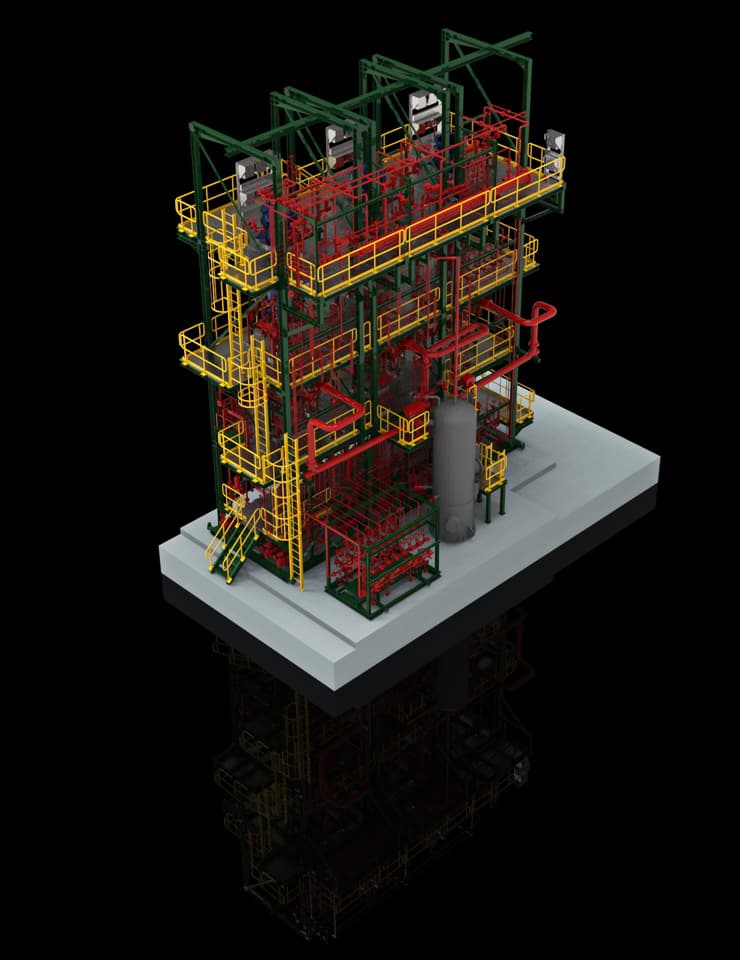

Fumes and dust collection and filtration systems involve localized suction as close as possible to the point of dust generation. The most frequently installed types of capture are:

- Open hood

- Enclosed hood

- Truncated cone hood

- Articulated suction arm

- Suction plenum

- Suction grid

Industrial dust collection is essential for workplace safety and is protected by D.L. 81/2008 for the protection of well-being and safety in the workplace.

Dust collection has various economic, organizational, and health benefits, including the possibility of saving on raw materials, longer machinery life, and optimization of production processes.

Contact us for receive more information about Dedusting Plants