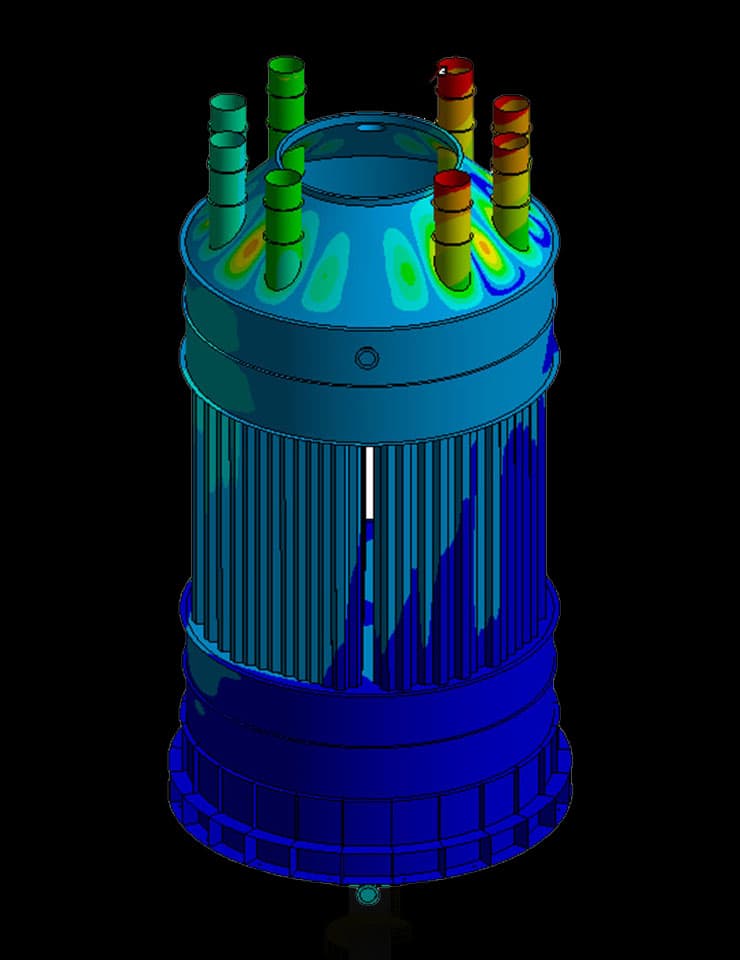

Pressure Vessel Calculation

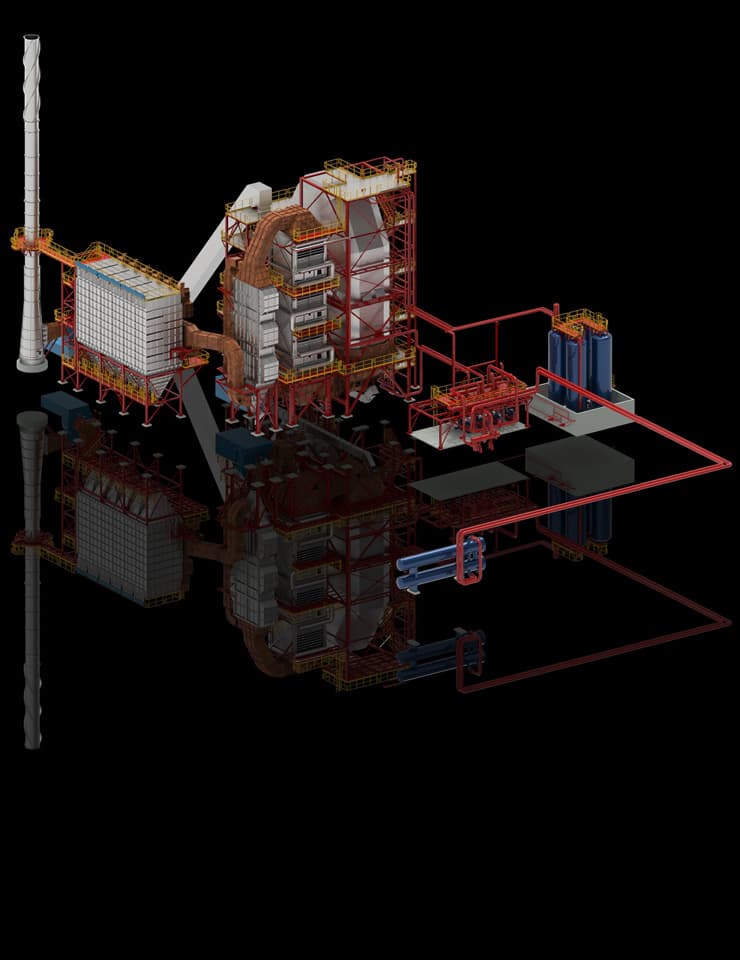

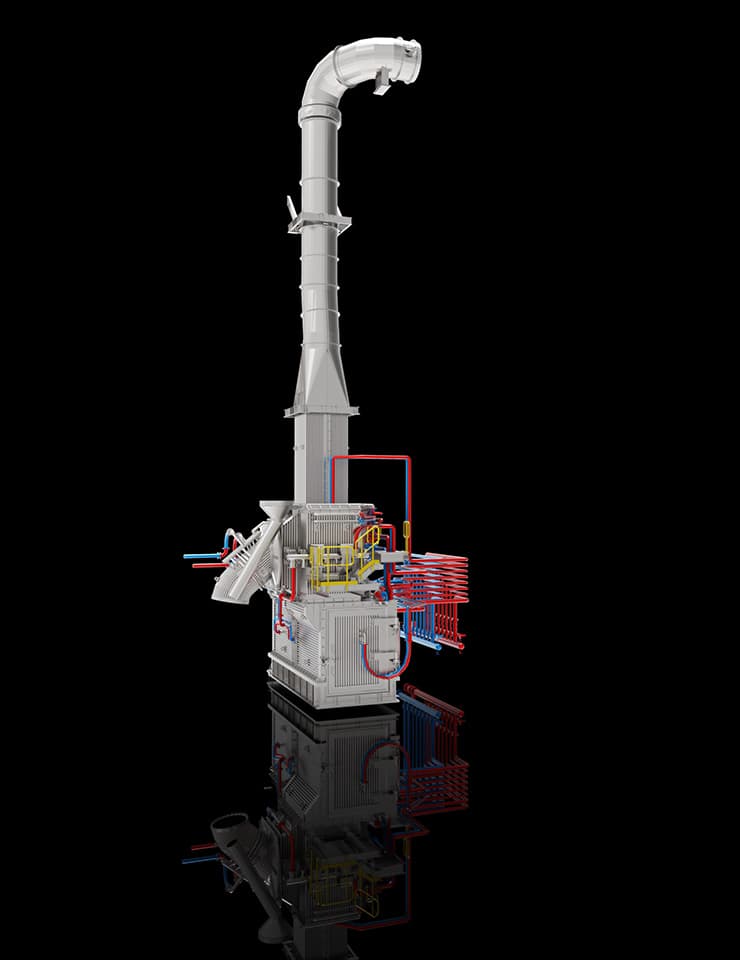

The construction and design processes of pressure equipment involve numerous technical disciplines. It is therefore essential to turn to technical structures capable of developing an effective multidisciplinary approach.

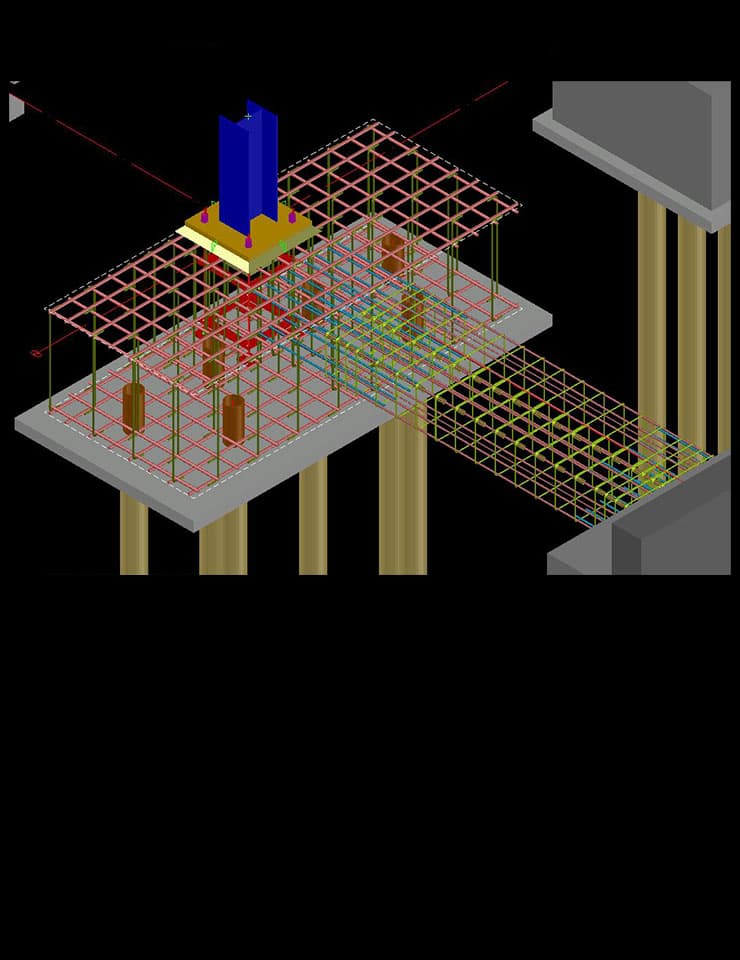

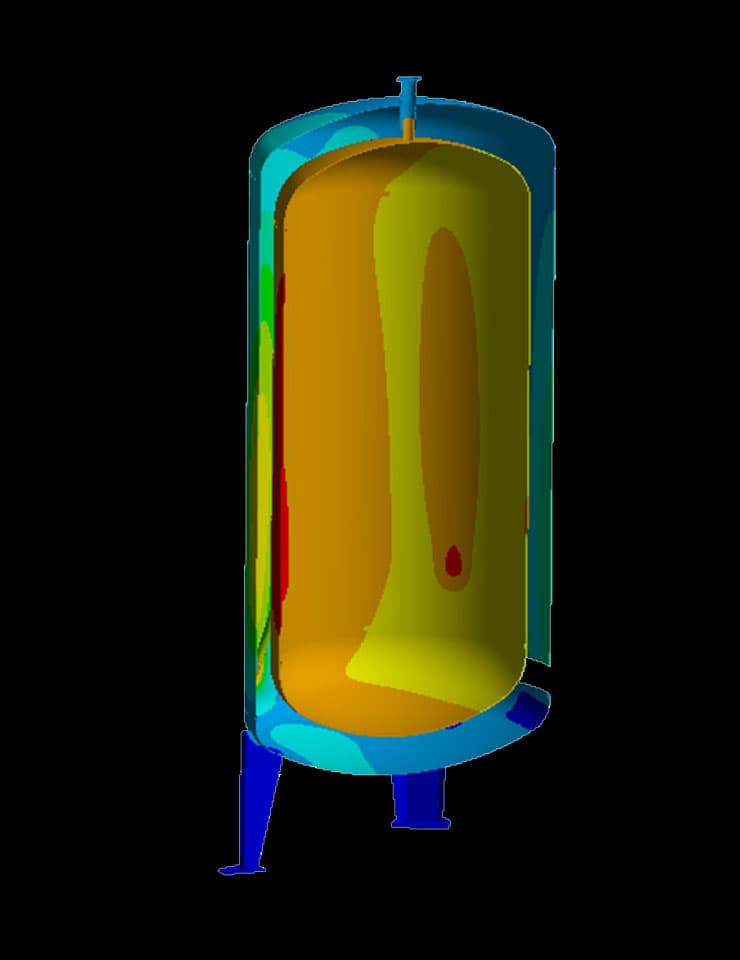

The production of pressure equipment involves the development of complex design activities such as calculations and drawings. In addition to this, a specific quality control plan is necessary for the processes involved: choice and procurement of materials, measuring instruments for checks and tests, qualification of welders and welding procedures, non-destructive tests, execution of final tests.

Among all the regulations or directives that regulate this sector, particular relevance is given to the ASME Boiler and Pressure Vessel Code (BPVC), EN13445 (Unfired Pressure Vessel), and the Pressure Equipment Directive (PED: 2014/68/UE) of the European Community. Specifically, ASME grants manufacturers the opportunity to apply its mark only after a specific and rigorous qualification and control process.

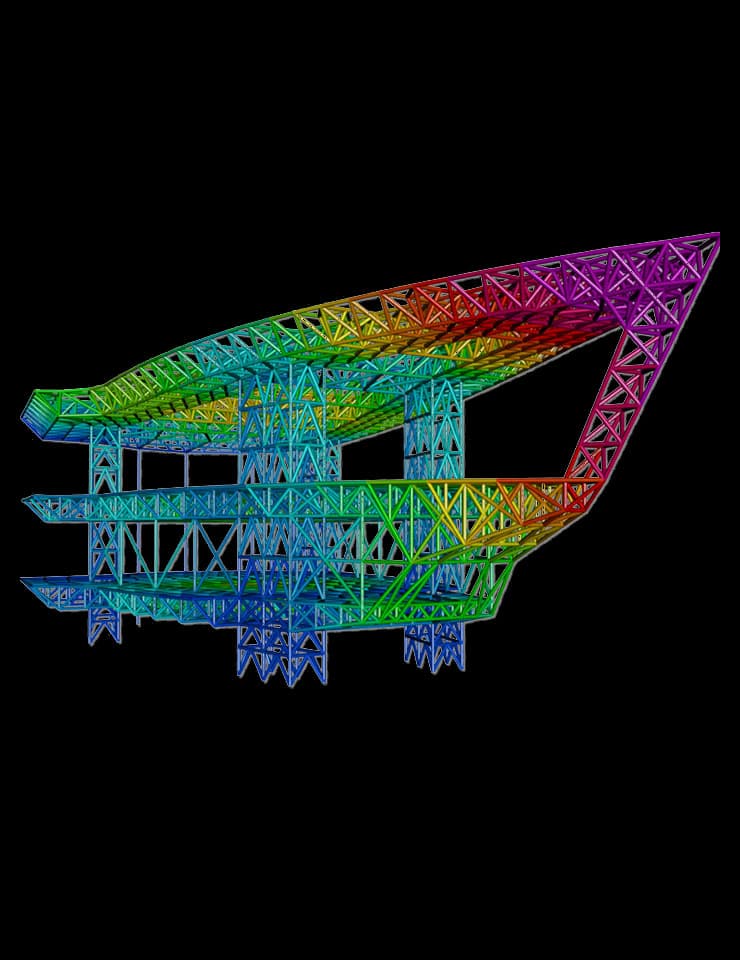

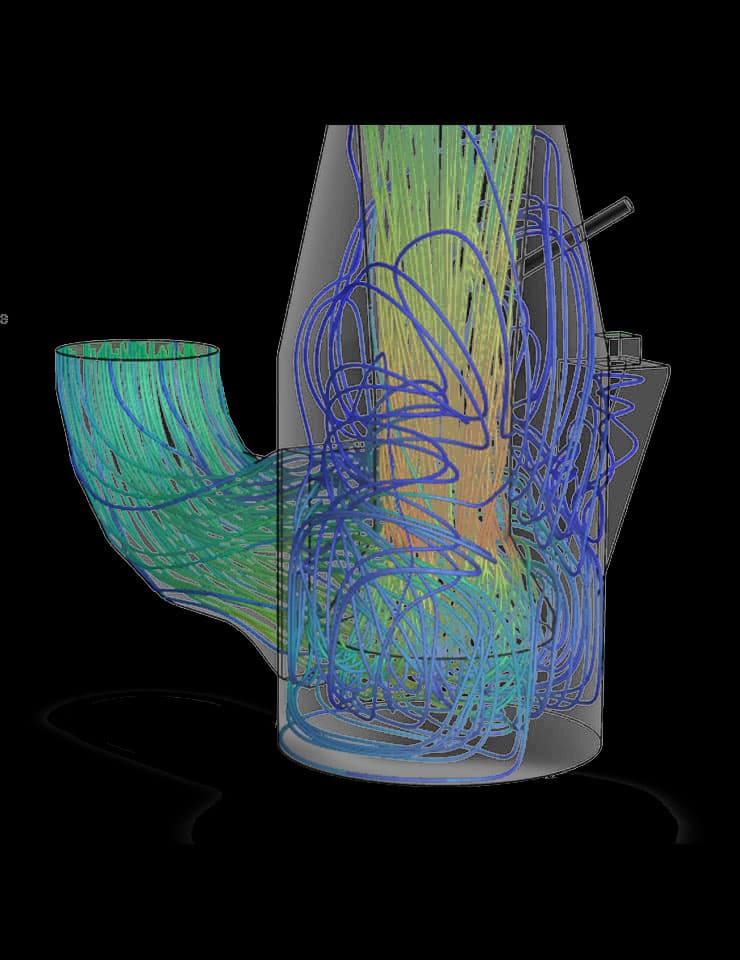

We specialize in the design of pressure equipment, strength and stability verification through specific software; we design piping systems, resistance and flexibility checks (Stress Analysis) according to ASME or EN standards.

Contact us for receive more information about Pressure Vessel Calculation